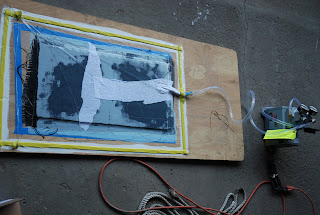

The mental hump of all of the daunting work left to be done on the Moth has been crested and I'm starting to roll down the other side quickly. With some nice, warm weather here (a little too warm) I've spent most of the weekend in the garage working on the Moth and parts. Things accomplished; fwd dolly bunk is complete and awaiting paint and installation this week, old main foil trunk and bulkhead is removed, rudder gusset is installed from scrap bulkhead, mast base frame has been shaped and awaits installation, two Laser centerboards repaired (side project), my brother's mainsheet keeper for his 505 boom is done and ready for shipping (side project) and the gentle hum of the vacuum pump is going on right now as the new bulkhead for the main foil trunk is curing. Tomorrow I'll lay up the forward bulkhead for the foredeck and then start to prep and install both bulkheads in preparation for laying up the deck next weekend. If I'm lucky, maybe even the foredeck too.